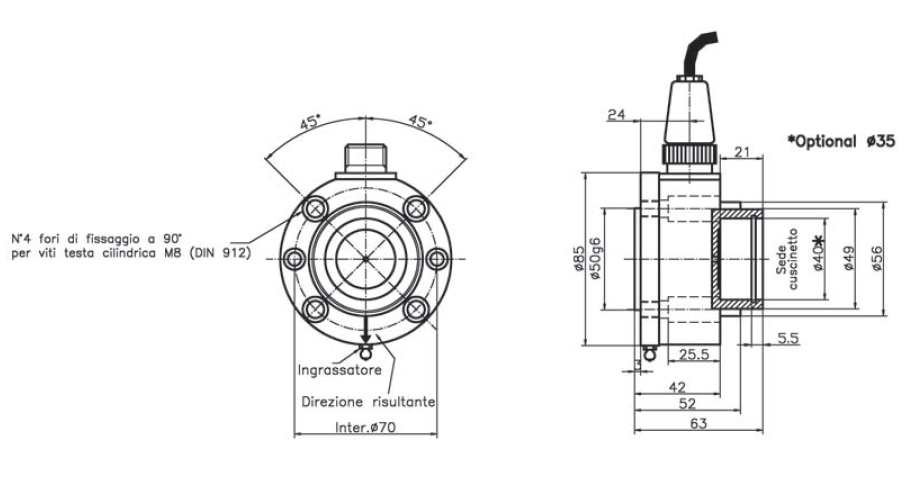

Rol load Flange

Possibility of lateral bearing greasing, easy to assemble, possibility of internal amplifier 4-20mA / 0-10V, for bearings Ø32, 35, 40, mm

![]() Click to enlarge image

Click to enlarge image

| Material | Stainless steel |

| Nominal load | 25, 50, 100, 200 kg |

| Limit load | 150 % F.S. |

| Breaking load | 300 % F.S. |

| Supply voltage | Vcc 18 Max |

| Output | 2 mV/V |

| Output tollerance | 0,1 % F.S. |

| Zero tollerance | 1 % F.S. |

| Linearity | 0,1 % F.S. |

| Hysteresis | 0,05 % F.S. |

| Reapeatability | 0,1 % F.S. |

| Input resistance | 350-360 ohm |

| Output resistance | 350-353 ohm |

| Insulation resistance | >= 2000 Mohm |

| Creep (30 Minutes) | 0,05 % F.S. |

| Thermal compensation | -10 / +40°C (14 / +104°F) |

| Operating temperature | -20 / +70°C (-4 / +158°F) |

| Temperature deviation zero | 0,003 % F.S. / °C |

| Temperature deviation full scale | 0,002 % F.S. / °C |

| Protection class | IP 54 |

| Connection | Panel male connector CR2R-07APNS |

| Standard cable length | Optional: Loose female connector CR2P-07ASNS-10 , connection cable 4 x 0,25 mm2 (length to be defined) |

| Type | CONNECTOR 7P SCC2A-16 |

| Length | 5 m (body lead cell not connected shield) |

| Pin 1 | + OUT |

| Pin 2 | - OUT |

| Pin 3 | NC |

| Pin 4 | NC |

| Pin 5 | NC |

| Pin 6 | + IN |

| Pin 7 | - IN |

General precautions to be followed in the installation and assembly of load cells: